Bonded Abrasives with Silicon Carbide

Overview

Bonded abrasives made with silicon carbide (SiC) are widely used for precision grinding, cutting, honing, and polishing. SiC’s high hardness, sharp cutting edges, and superior thermal conductivity make it ideal for shaping metals, ceramics, and non-ferrous materials.

Compared to alumina-based abrasives, silicon carbide provides faster cutting action, cleaner surface finishes, and reduced heat generation, especially when processing hard or brittle materials.

Application Scenarios

- Grinding Wheels: Used for cutting and grinding cast iron, carbide tools, and non-ferrous metals.

- Cutting Discs: Efficient for metal fabrication, foundry, and construction industries.

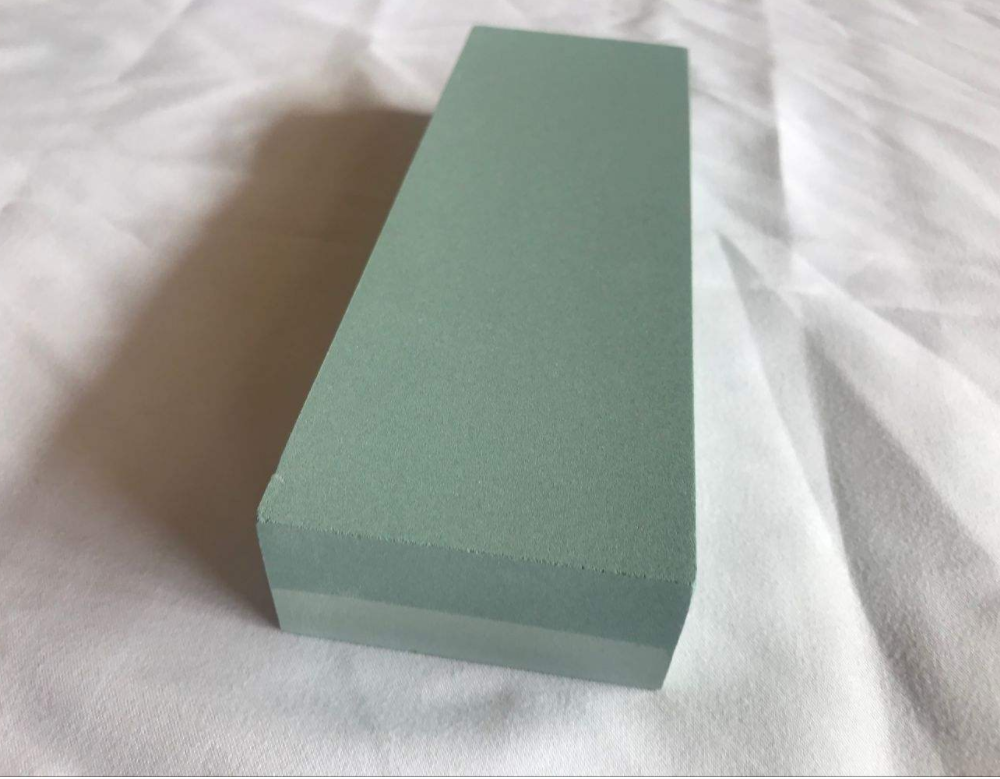

- Honing Stones: Ensure high dimensional accuracy and smoothness for engine parts and hydraulic cylinders.

- Polishing and Lapping Tools: Provide fine surface finish for ceramics, glass, and semiconductor materials.

Recommended Product & Grit Sizes / Grades

Both black and green silicon carbide are used in bonded abrasives depending on the material and finish required. Black SiC is suited for heavy-duty grinding, while green SiC is ideal for precision cutting and polishing applications.

| Application Type | Recommended Product | Typical Grit Size |

|---|---|---|

| Rough grinding and cutting | Black Silicon Carbide | F16 – F46 |

| Medium grinding / honing | Black Silicon Carbide | F60 – F100 |

| Fine polishing / lapping | Green Silicon Carbide | F150 – F400 |