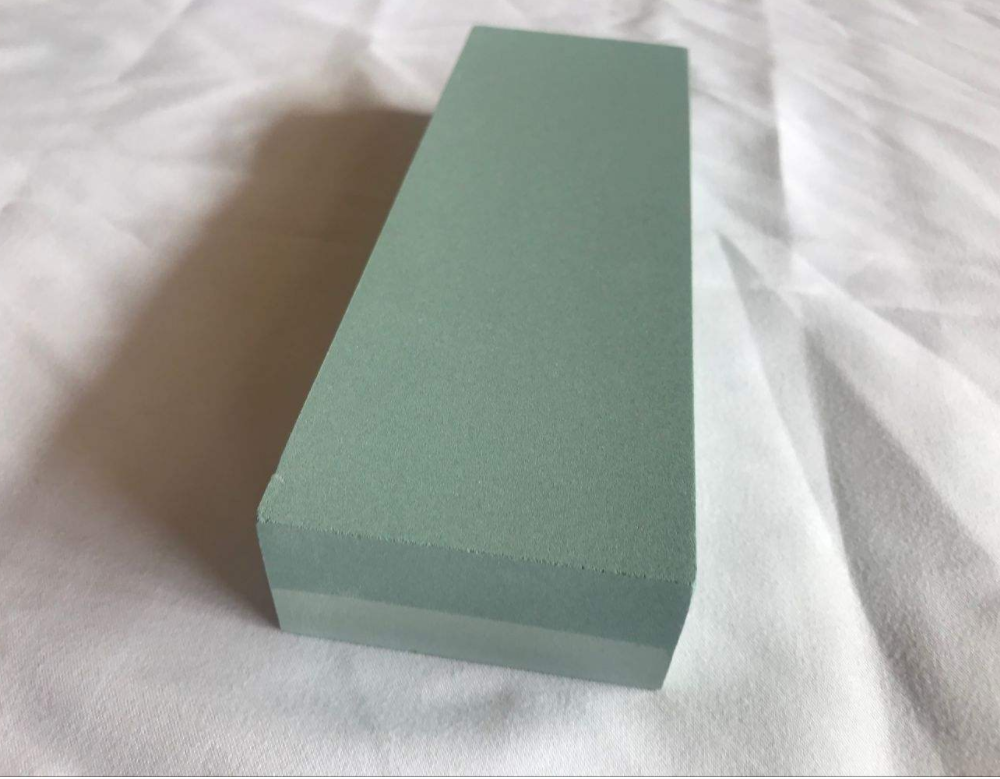

Optical Glass Polishing with Silicon Carbide

Overview

Green silicon carbide (SiC) is a preferred abrasive for precision optical glass polishing, including lenses, prisms, and mirrors. Its sharp cutting edges and high thermal conductivity help achieve flawless surfaces with excellent transparency and reflectivity.

Compared with traditional abrasives, silicon carbide provides superior removal rates and dimensional stability, ensuring high-quality polishing results in optical manufacturing.

Application Scenarios

- Lens Polishing: Used for spherical and aspherical lens finishing with sub-micron surface roughness.

- Mirror Surface Finishing: Ideal for telescope mirrors, laser optics, and reflective coatings.

- Prism and Filter Polishing: Ensures high flatness and optical clarity for precision components.

- Optical Glass Molding Preparation: Provides smooth pre-polish for subsequent molding or coating processes.

Recommended Product & Grit Sizes / Grades

Ultra-fine green silicon carbide powders are used in different polishing stages. The grit size selection depends on surface flatness, removal rate, and desired optical precision.

| Polishing Stage | Recommended Product | Typical Grit Size |

|---|---|---|

| Rough Polishing | Green Silicon Carbide | F400 – F600 |

| Intermediate Polishing | Green Silicon Carbide | F800 – F1000 |

| Final Polishing | Green Silicon Carbide (Micron Powder) | 1μm – 5μm |