Sandblasting with Silicon Carbide

Overview

Silicon carbide (SiC) is one of the most durable and efficient materials for sandblasting applications. Its extreme hardness (Mohs 9.2) and sharp-edged structure enable high-speed surface cleaning and texturing, making it ideal for removing rust, scale, and coatings from metal, ceramic, and composite surfaces.

Compared to traditional abrasives like aluminum oxide, SiC delivers faster material removal, produces more consistent roughness, and reduces media consumption due to its superior wear resistance.

Application Scenarios

- Metal Surface Cleaning: Ideal for removing rust, paint, and oxide layers without deforming the base material.

- Ceramic and Composite Preparation: Creates micro-textured surfaces that enhance coating adhesion and bonding strength.

- Mold and Tool Maintenance: Provides precision cleaning for molds, dies, and industrial tools with minimal residue.

- Surface Activation: Used before coating or plating to improve wettability and bonding performance.

Recommended Product & Grit Sizes / Grades

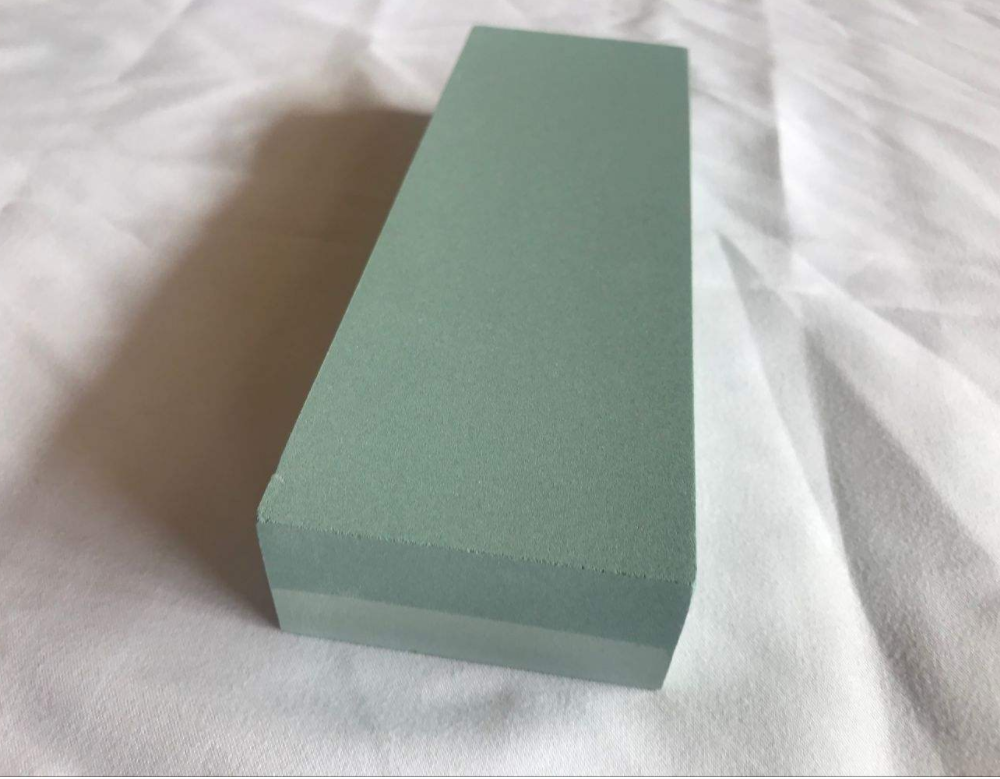

For different blasting requirements, both black and green silicon carbide grades can be selected. Black SiC is preferred for general heavy-duty cleaning, while green SiC is used for finer finishing where surface precision is critical.

| Application Type | Recommended Product | Typical Grit Size |

|---|---|---|

| Heavy-duty rust removal | Black Silicon Carbide | F16 – F36 |

| General surface preparation | Black Silicon Carbide | F46 – F80 |

| Fine surface texturing | Green Silicon Carbide | F120 – F240 |