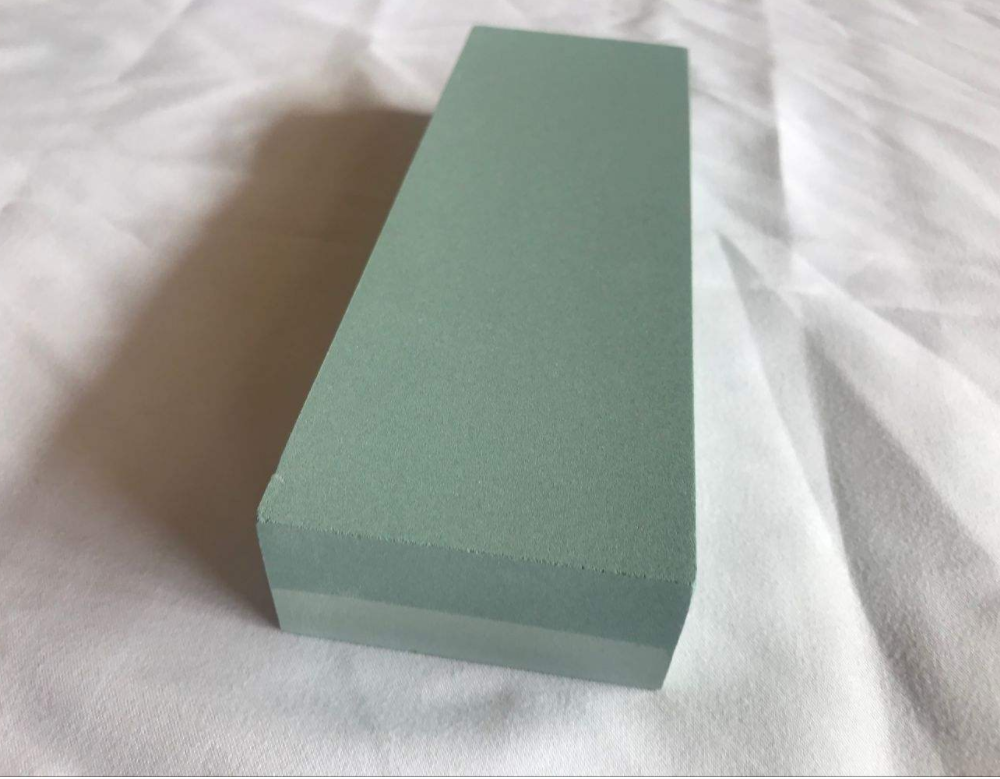

Superfinishing Stone with Silicon Carbide

Overview

Superfinishing stones embedded with green or black silicon carbide are used for ultra-precision surface finishing. They provide exceptional flatness, low roughness, and high consistency for metallic and composite components.

These stones are widely applied in aerospace, automotive, bearing, and mold industries where surface quality and dimensional accuracy are critical.

Application Scenarios

- Precision Bearings: Achieves ultra-smooth races and rolling surfaces, reducing friction and wear.

- Mold and Die Finishing: Provides high-quality surface polish for plastic injection and metal dies.

- Aerospace Components: Ensures critical flatness and surface integrity for hydraulic and pneumatic parts.

- Metal and Composite Lapping: Produces consistent surface finish for aerospace, automotive, and optical components.

Recommended Product & Grit Sizes / Grades

Green silicon carbide is typically used for fine finishing, while black silicon carbide is suitable for harder substrates. The grit size selection depends on the desired smoothness and surface precision.

| Application Type | Recommended Product | Typical Grit Size |

|---|---|---|

| Heavy-duty finishing | Black Silicon Carbide | F46 – F80 |

| Medium precision finishing | Green Silicon Carbide | F100 – F220 |

| Ultra-fine finishing | Green Silicon Carbide Micron Powder | 1μm – 5μm |