About Our Factory

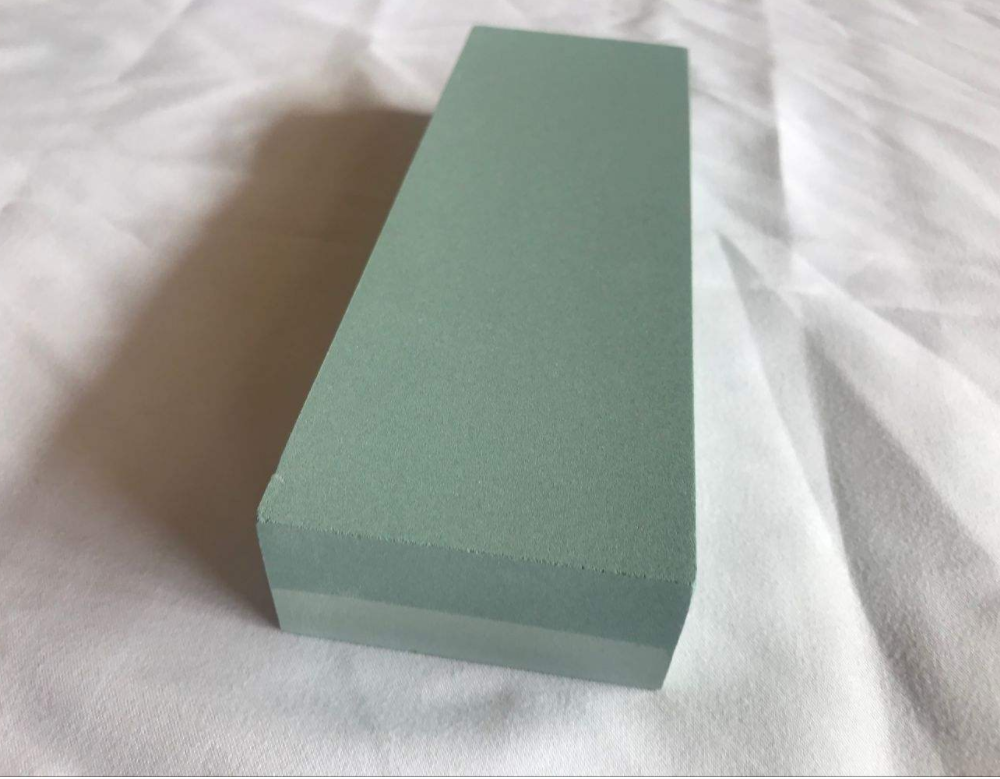

With over 20 years of expertise in abrasive manufacturing, we operate advanced crushing, grading, and magnetic separation lines to produce high-purity black and green silicon carbide.

Advanced Production

Modern automated lines ensure stable quality and efficiency.

Quality Certified

ISO 9001 certified with strict quality control system.

Global Reach

Products exported to over 30 countries worldwide.

Expert Team

20+ years of manufacturing and technical experience.